Detailed analysis of working principle

3.1 Paper feeding and pretreatment

3.2 Intelligent forming of honeycomb structure

3.3 Efficient gluing and hot pressing technology

3.4 Unwinding, rewinding and cutting

3.5 Quality inspection and packaging

Introduction

In the current packaging industry environment, the fiercely competitive market environment has also led to increasingly fierce price wars and diversified packaging materials, but honeycomb paper is indeed the most popular packaging material at present.

This also has to say about the market chain reaction. The increasing demand for online shopping has also increased the demand for express transportation and logistics, and the transportation logistics supply chain costs have increased accordingly. One of the key points to reduce transportation costs is to choose the right packaging materials.

The fully automatic honeycomb paper making machine plays the role of a producer, continuously providing honeycomb paper to the market. This article will explore the working principle of the fully automatic honeycomb paper making machine in depth and reveal the intelligent technology and innovative design behind it.

What is the honeycomb paper making machine?

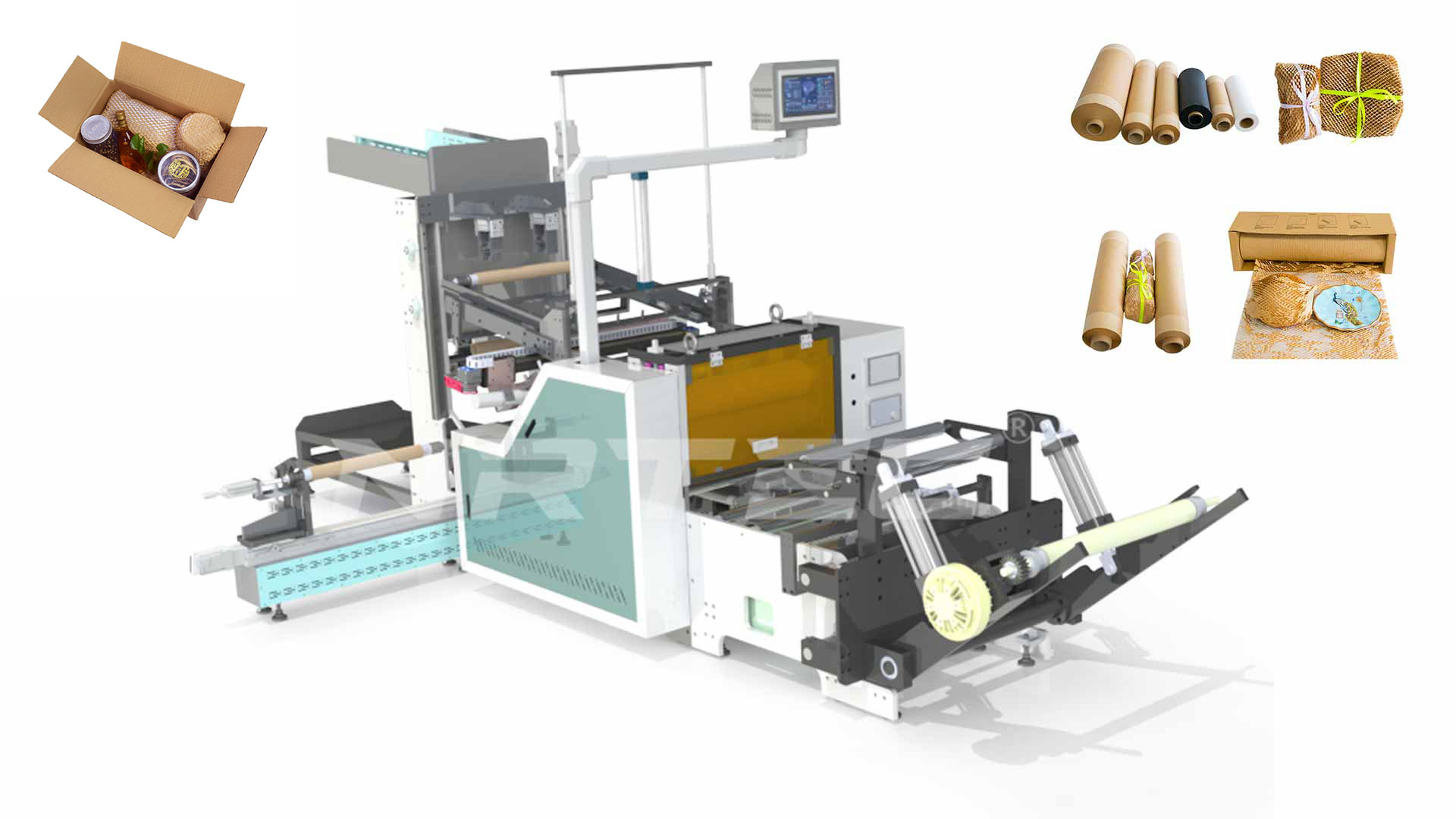

Definition: The fully automatic honeycomb paper making machine is a production equipment that integrates automation and intelligence. It can produce honeycomb paper on a large scale. From raw material supply to honeycomb paper forming, it is fully automated, which can reduce manual dependence and improve production efficiency.

Honeycomb paper making machine is designed for automatic production of honeycomb wrapping paper. The general production process is summarized as follows: the rolled kraft paper roll is fixed on the unwinding machine of the honeycomb paper making machine, passes through the cutting roller, and then rewinds and cuts a small hole with a prop, and pulls it open to form a honeycomb wrapping paper roll.

The machine mainly includes a series of technical production processes such as paper feeding, unwinding, winding and rewinding, forming and cutting, forming a closed production system.It is mainly made by gluing two layers of kraft paper together with a honeycomb layer in the middle.

The automation architecture of the honeycomb paper cutting machine includes: automatic paper tube loading, automatic air shaft loading, automatic air extraction, automatic placement of air shaft, automatic winding of air shaft, automatic placement of finished products, automatic feeding device and automatic deviation correction system.It is a papermaking machine used to make honeycomb paper, which is mainly composed of a mesh forming machine, a honeycomb machine and a bonding machine.

Detailed analysis of the working principle

Paper feeding and pretreatment

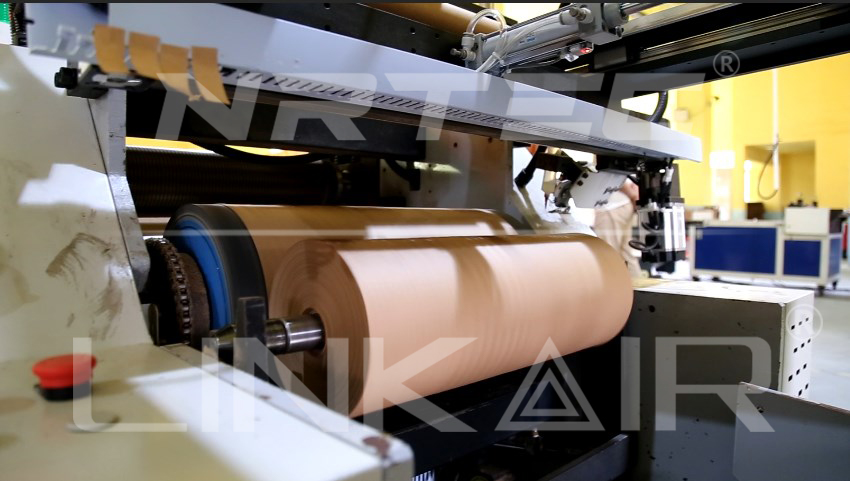

First, paper feeding requires accuracy and balance, so this step requires manual operation. Push the kraft paper roll in and insert the air shaft tube to inflate it and then lock it. Then, pass the paper through the air pipe, cutter, etc. in an S shape (note: when passing through the cutter, you need to press the button next to it to assist in entering). After the paper is passed, production pre-processing is carried out.

Intelligent forming of honeycomb structure

After the kraft paper is fed in, a series of knives inside the machine will score it, and these knives form small uniform cuts in the paper,after setting the cutting length, speed and number of meters on the touch screen, it will be accurately cut and punched through the automatic winding air shaft and automatic deviation correction system through the precise control of the computer background, and it will present a hexagonal structure after stretching.

Efficient gluing and hot pressing technology

After the kraft paper is fed in, it will pass through a series of rollers inside, and then the two layers of kraft paper and the honeycomb paper layer are bonded together through uniform coating technology. The temperature and time are precisely controlled by the temperature control system of the hot press unit to complete the bonding step of the honeycomb paper.

Unwinding, rewinding and cutting

The honeycomb paper cutting machine has automatic unwinding and feeding functions. After the paper passes through the cutter, it will automatically enter the rewinding, gluing and cutting, forming a honeycomb paper roll and then feeding it to the pallet for stacking and collection.Its maximum paper material cutting width is 550mm.

After this step is completed, the machine will automatically unwind and rewind to enter the next roll production process.

Quality inspection and packaging

For each roll of honeycomb paper produced, the technical staff will tear off 1m to check the honeycomb paper forming situation, and will affix a label to the honeycomb paper tube core of each roll so that it can be traced back to the production source later. After affixing, it will be packaged, and we accept the customization of logo, color and pattern for this carton outer packaging.

Highlights of technological innovation

Fully automated and intelligent: fully automated frequency converter control is adopted, and the entire production process is fully automated, reducing manual dependence and errors, and optimizing the production process.

Efficiency management: through the intelligent drive setting system, the energy utilization is maximized and energy consumption is reduced.

Environmentally friendly materials: sustainable kraft paper raw materials are selected to improve the recyclability of current packaging materials

Conclusion

The fully automatic honeycomb paper making machine not only changes the production method of packaging, but also promotes the entire industry to move towards a more efficient, intelligent and environmentally friendly direction.