Introduction:

With the rapid development of the packaging industry, honeycomb paper making machines, as key equipment for producing environmentally friendly, lightweight and durable packaging materials, are increasingly in demand.

Against this backdrop, in the packaging market, a certain industry leader, Xingrui Packaging, and Meixun Machinery have joined forces to bring the after-sales service of honeycomb paper making machines to a new level through technological innovation and excellent service.

1. Formulate maintenance plans to extend the life of equipment

For a large machine, regular and correct maintenance and maintenance of the machine is the key to extending its service life and one of the important means. Therefore, the company provides detailed maintenance and maintenance instructions to help customers understand how to properly maintain the honeycomb paper making machine to extend the service life of the equipment. These instructions include regular inspection, cleaning and replacement of necessary parts (wearing parts) to ensure that the equipment is always in the best operating condition.

2. Provide excellent customer service

In order for customers to be able to effectively use the product as soon as they receive it, it provides comprehensive customer service and support. Including providing equipment installation videos, usage videos, debugging and operation videos, all of which will be filmed and provided by dedicated and experienced R&D personnel to ensure that customers can quickly get started and maximize the use of equipment in production. In addition, it also has a 3-to-1 after-sales service, which can quickly respond to customer problems and ensure that customer problems can receive timely feedback and technical support.

3. Technological innovation promotes the development of the packaging market

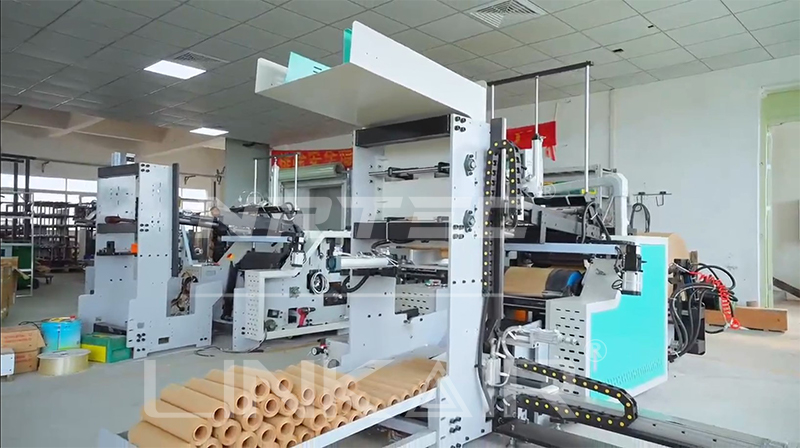

The honeycomb paper making machine, through automation technology and intelligent background operation settings, adopts a fully integrated circuit variable frequency speed control system, which can automatically unwind, rewind and cut the production, not only improving production efficiency, but also reducing energy consumption. The application of this innovative technology enables the company to provide packaging materials self-sufficiently and provide them to local logistics warehouses for use, broadening the business chain and improving its own competitiveness.

Today, when environmental protection and sustainability have become a global consensus, the innovation and high-quality service of honeycomb paper making machines are particularly important. The cooperation between Xingrui Packaging and Meixun Machinery not only provides customers with high-quality products and services, but also sets a new benchmark for the entire industry. With the continuous advancement of technology and the continuous expansion of market demand, we have reason to believe that the after-sales service of honeycomb paper making machines will continue to reach new heights.

What professional tools are needed to maintain the honeycomb paper making machine?

When maintaining the honeycomb paper making machine, a series of professional tools are needed to ensure the normal operation of the equipment and extend its service life. The following are some commonly used professional tools:

*Screwdrivers and wrenches: used for daily tightening and loosening screws, they are basic tools in maintenance work.

*Lubricants: such as lubricating oils and greases, used to reduce friction between mechanical parts and prevent wear.

*Cleaning tools: including brushes, vacuum cleaners, etc., used to remove paper dust and waste from the equipment and keep the equipment clean.

*Measuring tools: such as calipers, gauges, etc., used to check and ensure the dimensional accuracy of components.

*Electrical testing tools: such as multimeters, insulation resistance testers, etc., used to detect the status of electrical equipment and ensure the safety and stability of electrical systems.

*Cutting tools: such as blades, cutting machines, etc., used to cut honeycomb paper and other materials.

*Manual or electric stretching machine: used to expand die-cut kraft paper into a 3D honeycomb structure to enhance the buffer structure effect.

*Maintenance records and troubleshooting procedures: Establish detailed maintenance records and troubleshooting procedures to help timely discover and solve problems.

*Professional training: Provide professional training for operators to familiarize them with the operation, maintenance and adjustment of the equipment and solve common faults in a timely manner.

*Spare parts and replacement parts: such as bearings, seals, belts, etc., for regular replacement and maintenance of equipment.

*Inspection tools: such as endoscopes, stethoscopes, etc., used to check the internal status and operating sounds of the equipment to detect abnormalities in a timely manner.

*Pressure and temperature measuring equipment: used to monitor the pressure and temperature of the equipment during operation to ensure that it works within a safe range.

Using these professional tools, combined with regular maintenance and inspection, the stable operation of the honeycomb paper making machine can be effectively maintained, the occurrence of faults can be reduced, and production efficiency can be improved.