Introduction

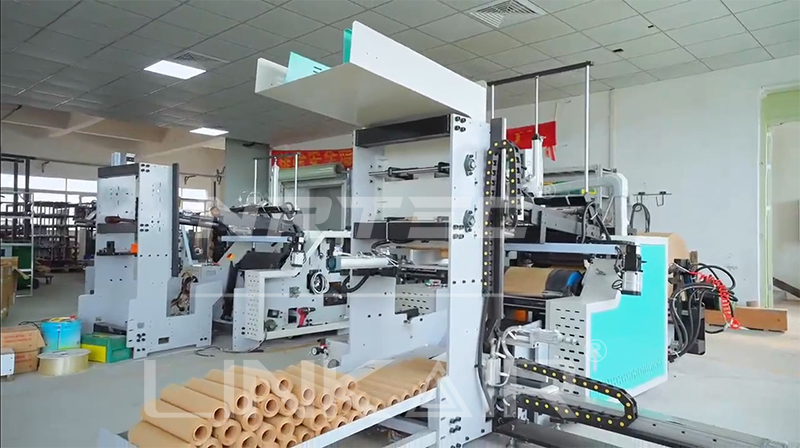

Honeycomb paper cutting machines, also known as honeycomb paper making machines, are automated precision production machines that can quickly and accurately cut and rewind kraft paper to form honeycomb packaging paper. They can cut honeycomb paper of various sizes quickly, efficiently and accurately, improving overall production efficiency.

What Is A Honeycomb Paper Cutting Machine?

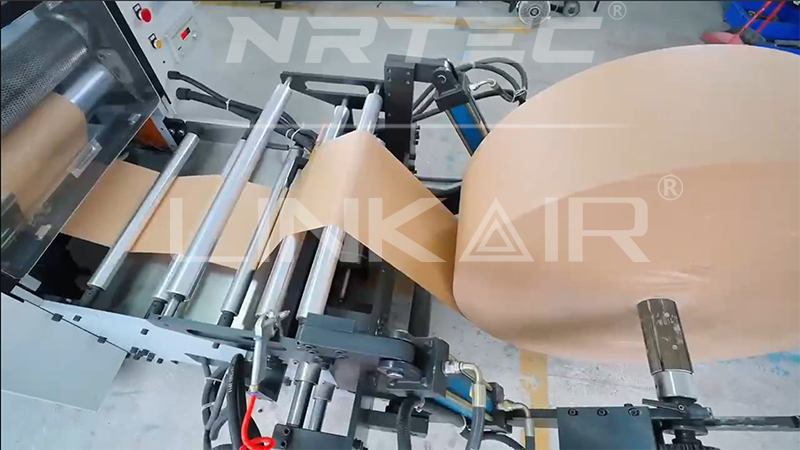

Honeycomb paper cutting machine is often used as a special production equipment to form honeycomb shape by threading, rewinding, cutting and rewinding large rolls of kraft paper. It is simple to use as a whole, with a stable inverter and automatic correction system, which can accurately cut kraft paper into honeycomb paper of different sizes, just set it on the touch screen.

Honeycomb paper is widely used in the packaging industry due to its light weight, durability, high strength, and roadside recyclability. It is also a substitute for plastic foam packaging. This machine is used to die-cut kraft paper. After cutting, countless hexagons are formed on the surface. When it is stretched, it is a 3D honeycomb shape. It has the advantages of high compressive strength and good buffering performance. It is an environmentally friendly green material.

Under PLC control, this machine integrates unwinding, die cutting and rewinding to realize intelligent automatic operation. The machine is equipped with a programming device between the die cutting position and the unwinding position to ensure stable and reliable rewinding operation, which can be freely adjusted. This machine has functions such as automatic counting and alarm of rewinding length, compact structure and easy use.

Benefits Of Using Honeycomb Paper Making Machine

For the packaging industry, using honeycomb paper making machine has many advantages and wide applications:

1. Automation: It can automatically replace paper tubes, cut and rewind, reduce manual intervention and improve efficiency.

2. Simple operation: Equipped with an automation system and an integrated circuit variable frequency speed control system to ensure stable output.

3. Efficient and accurate: The machine can quickly and continuously cut honeycomb paper from kraft paper at a speed of 280 meters per minute, meeting the production needs of most enterprises.

4. 100% recyclable: Honeycomb paper is made of recyclable kraft paper, which is an environmentally friendly packaging material that is easy to degrade and environmentally friendly.

5. Cutting accuracy: The machine uses precise cutting technology to ensure that the cut honeycomb paper is accurate in size and consistent in shape.

6. Versatility: Different sizes of honeycomb paper can be produced according to different needs, such as: 50cm, 38cm or 30cm wide, to meet diverse packaging needs.

Why is a honeycomb paper cutting machine the perfect tool for your business?

If you are looking for a solution to save procurement costs and expand the industrial chain, then the fully automatic honeycomb paper making machine can help you. Not only can you quickly produce honeycomb paper as an environmentally friendly packaging material, but in the process you can also simplify the procurement process and reduce costs, and expand the business chain. Honeycomb paper can be fully utilized and provided to local logistics warehouses, Amazon and some packaging industries.

When buying a honeycomb paper cutting machine, you need to consider some factors, such as the size of the machine and the type of paper to be used. But in general, a honeycomb paper making machine is a huge and beneficial investment for any company that needs to produce a large amount of honeycomb paper.

Conclusion

In short, the honeycomb cutting machine is the perfect tool for any business that needs to cut paper quickly and efficiently. It is easy to use and can cut paper into the size you need. In the long run, it can save time and money for the company.