Introduction:

In the modern packaging industry, the application of automation technology is becoming more and more widespread, especially the automatic honeycomb paper making machine production line, which has become the first choice for many companies due to its high efficiency, environmental protection and economic characteristics. This article will explore in depth the key factors to consider when you choose to invest in an automatic honeycomb paper roll making machine production line, how to use it correctly and what to pay attention to, and provide suggestions for choosing a suitable supplier.

Considerations when choosing an automatic honeycomb paper making machine production line:

1. Production line scale and degree of automation: The scale and degree of automation of the production line directly affect production efficiency and cost. The larger the scale, the higher the degree of automation, and the higher the price is usually. Enterprises should choose a suitable production line based on their own production needs and budgets.

2. Process configuration: Different process configurations have different requirements for equipment and different prices. Enterprises need to consider key process links such as paper pretreatment, honeycomb core production, core paper bonding, and cardboard molding.

3. Brand and quality: The equipment quality and technical level of different brands and manufacturers vary greatly, and the price will also vary. Choosing well-known brands and high-quality equipment can ensure the stability of production and the reliability of products. However, it is not ruled out that some niche brands will have the same quality and better services to choose from.

4. After-sales service: The after-sales service level of the equipment, such as installation and commissioning, repair and maintenance, will also affect the final quotation and user experience

Precautions for the correct use of the automatic honeycomb paper making machine production line:

*Material selection: Selecting high-quality paper core is conducive to the formation of honeycomb paperboard and reduces deformation, wrinkling and looseness during the production process.

*Temperature control: Control the temperature of the shaping oven and the pressing oven, as well as the pressure of the press, to ensure the normal production of the honeycomb paperboard production line.

*Speed adjustment: Pay attention to the conveying speed of the paper placing, gluing, drying and other processes, as well as the control of the amount of glue, which are key factors affecting the production of high-quality honeycomb paperboard.

*Equipment maintenance: Regularly maintain and calibrate the equipment to maintain the best working condition and extend its service life.

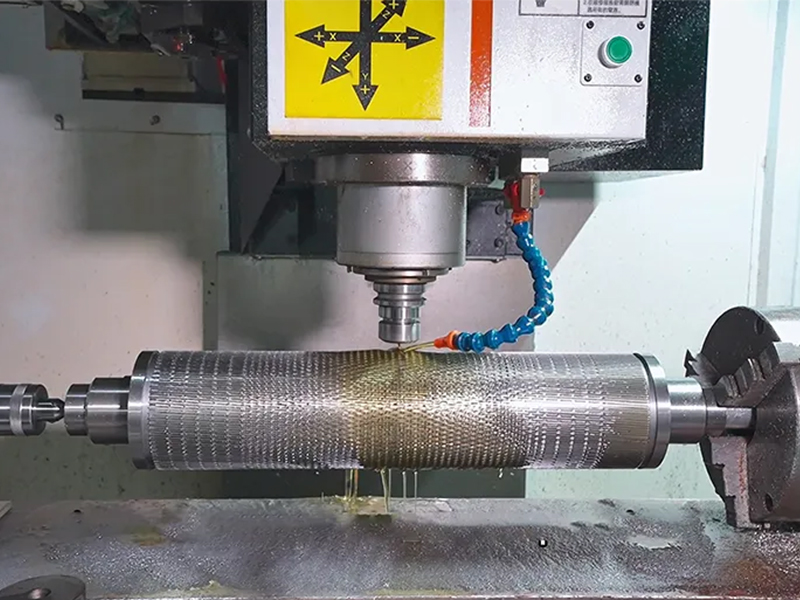

Gluing process

Automatic winding and unwinding

Choose a suitable honeycomb paper making machine supplier:

*Professional experience: Choose suppliers with rich experience and professional technology, who can provide a full range of services from equipment supply to technical support.

*Customized service: Excellent suppliers can provide customized solutions according to the specific needs of customers.

*Environmental protection and energy saving: Choose suppliers that use environmental protection and energy-saving technology, which not only meets the requirements of sustainable development, but also reduces long-term operating costs.

*Quality assurance: Suppliers should provide reliable quality equipment and have a complete after-sales service system to ensure that customers can produce smoothly.

* After-sales service: Instant response to product usage issues and professional engineers to answer questions can reduce product downtime and obtain a high-quality purchasing experience.

In summary, the selection of automatic honeycomb paper roll making machine production line is a process of comprehensive consideration of multiple factors. Correct selection and use can not only improve production efficiency, but also ensure product quality while reducing operating costs. Choosing a reliable supplier will provide solid support for the long-term development of the enterprise.