Introduction

As environmentally friendly packaging becomes increasingly popular, honeycomb paper making machines have become the core equipment of more and more small and medium-sized packaging factories. Whether you serve the e-commerce, manufacturing or logistics industries, how to efficiently use equipment, increase production capacity and reduce labor costs are the key to determining profitability.

This article will share with you 5 practical tips to help you maximize the capacity of honeycomb paper making machines and lay a solid foundation for your business growth.

Tip 1: Rationally plan the production paper roll specifications to reduce roll change time

Every time the paper roll width or paper material type is changed, the equipment needs to be stopped for adjustment and calibration.

Solution:

* When receiving orders, orders with similar specifications are scheduled together to uniformly produce paper rolls of the same size;

* Use the multi-parameter preset function of the machine to save common specification configurations in advance and switch quickly;

* Ensure the use of base paper with stable quality to reduce the time waste caused by frequent debugging due to paper material problems.

Tip 2: Use fully automatic unwinding and rewinding modules to achieve continuous operation

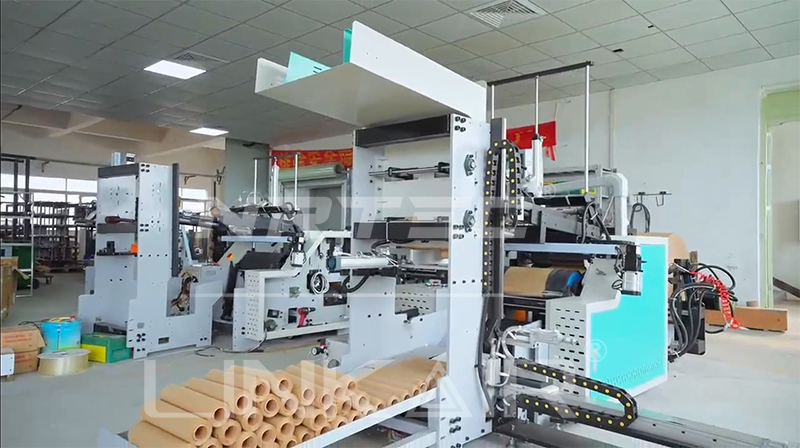

Our automatic honeycomb paper making machine supports automatic unwinding-pressing-unfolding-forming-cutting-rewinding integrated operation, greatly reducing the frequency of manual participation.

Recommended configuration:

*Intelligent tension control system to ensure that the paper is always in constant tension to avoid paper jams and breaks;

*Dual roll backup system: automatically switch to the second roll after one roll is used up to improve continuous operation capacity;

*Automatic alarm can be set when the roll is full to remind workers to replace the empty shaft in time without stopping the machine.

Tip 3: Regularly clean and check the embossing and cutting modules

Embossed rollers and cutting knives are key components that affect the quality of honeycomb paper molding and cutting efficiency.

Recommendations:

* Clean the honeycomb mold with a dry brush or air gun after daily operations;

* Check the sharpness of the cutting knife every week, and replace or polish it in time when it is passivated;

* Regularly lubricate the drive shaft and bearing positions to keep the machine running smoothly.

* Keeping these core parts clean, precise, and flexible will help improve paper output fluency and reduce scrap rates.

Tip 4: Optimize operator skill training and division of labor

Even the most advanced equipment needs skilled operators to maximize its performance. Many customers are inefficient in the early stage of purchasing equipment, mainly because of unskilled operation or unclear division of labor.

Suggested measures:

*Develop a standard operating procedure (SOP) and post it next to the machine;

*Each employee is responsible for a fixed operation link, such as paper placement, control console, and rewinding;

*Arrange the manufacturer to provide remote video training or on-site debugging training (if conditions permit) to ensure that each employee understands the principle of the machine.

Tip 5: Use the intelligent parameter setting function to improve adaptation efficiency

Our full automatic honeycomb paper making machine supports touch screen parameter adjustment and memory saving functions. You can further improve efficiency in the following ways:

* Set parameter files for commonly used paper roll sizes in advance, such as width, unfolding ratio, cutting length, etc.;

* Quickly call preset programs during production to avoid manual repeated testing;

* The visual interface reduces the risk of misoperation and is especially friendly to novices.

Through digital control, the idling time of the machine can be greatly reduced, making every minute profitable.

Conclusion

The performance of honeycomb paper making machine depends not only on the equipment itself, but also on how you use it. Through practical skills in five aspects, including scientific production scheduling, automation coordination, regular maintenance, personnel training and intelligent settings, even small and medium-sized packaging factories can quickly increase production capacity, reduce unit paper roll costs, and truly maximize the value of equipment.

Don't wait until orders are piled up before thinking of ways to improve efficiency. Starting today, let honeycomb paper machine automatic equipment become the most powerful productivity tool in your team.