Introduction

In the modern packaging industry, air column bags, as an environmentally friendly and efficient packaging material, have gradually become the preferred solution to replace traditional plastic packaging. The air column bag making machine production line is the core equipment for producing air column bags, which can meet the needs of enterprises for high-quality and high-efficiency packaging materials.

This article will introduce the functions, advantages and application scenarios of the air column bag making machine production line in detail to help buyers better understand this product.

What is the air column bag making machine production line?

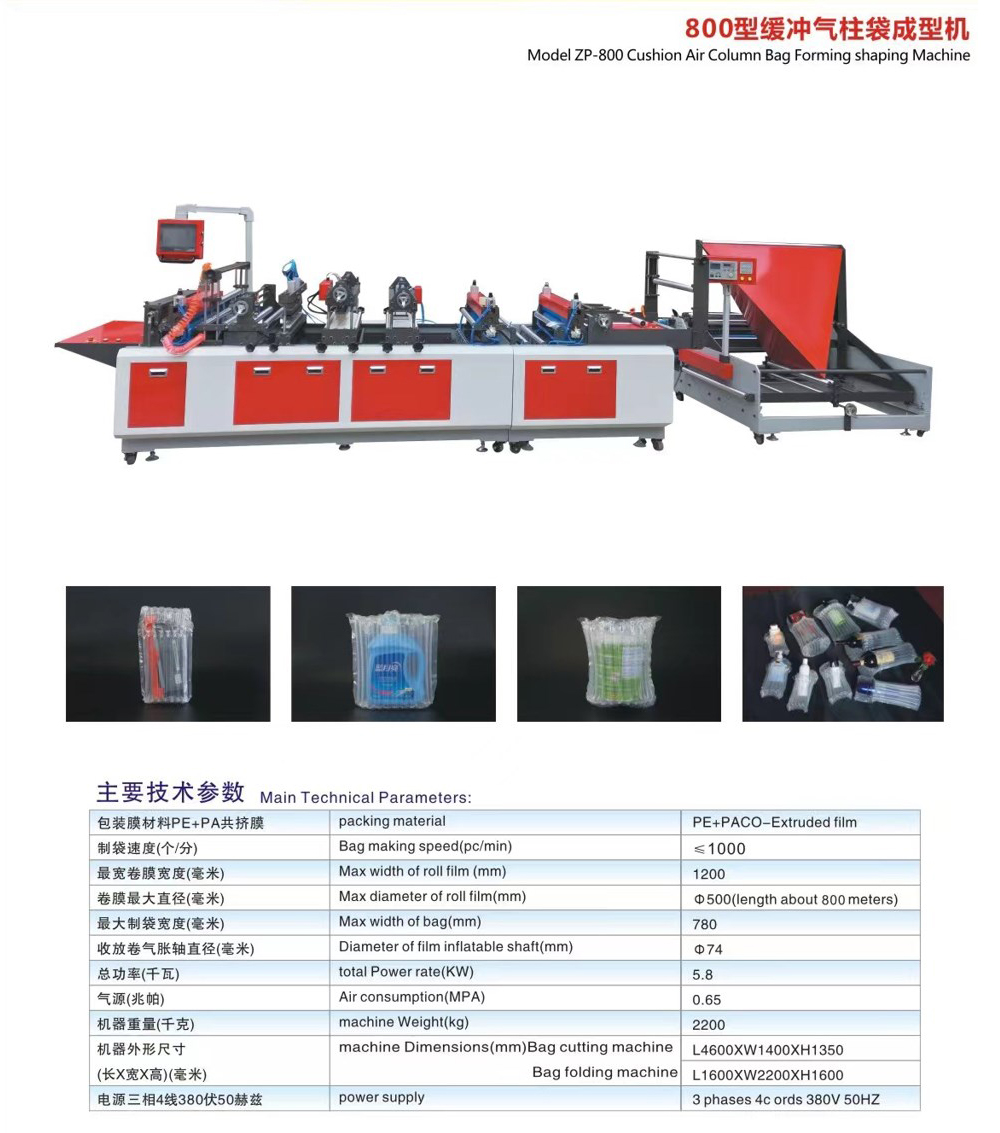

The air column cushion bag making machine production line is an automated production equipment for producing air column bags (also called air cushion film). It heats, shapes, inflates and seals plastic film to make packaging bags with air column structure.

This structure can not only effectively cushion and protect the product, but also has the characteristics of lightweight, environmental protection and economy.

Advantages of air column cushion bag making machine production line

1.Efficient production and improved production capacity

The air column bag making machine production line adopts automation technology, which can produce air column bags quickly and continuously, significantly improving production efficiency. Compared with traditional manual production, the automated production line can greatly reduce production time and meet the needs of large-scale orders.

2. Energy saving and environmental protection, in line with sustainable development

The main material of the air column bag is recyclable polypropylene (PP) film. Compared with traditional plastic packaging, its production process is more environmentally friendly, and the product can be reused or recycled, which is in line with the trend of green packaging.

3. Customized production to meet diverse needs

The air column bag roll making machine production line supports customized production, and can adjust the width, length, air column spacing and number of layers of the air column bag according to customer needs to meet the packaging needs of different products.

4. Reduce transportation costs

The lightweight design of the air column bag can reduce the weight and volume of the packaging material, thereby reducing logistics costs.

In addition, its excellent cushioning performance can effectively reduce the damage rate of products during transportation.

5. Automated operation, reducing labor costs

The air column cushion bag making machine production line is usually equipped with an automated control system, which is simple to operate and easy to maintain, reducing dependence on manual labor and reducing labor costs.

Working principle of air column bag roll making machine production line

1. Raw material input The production line starts with a roll of plastic film, which enters the production line through a feeding device.

2. Heating and forming The film passes through a heating device to soften it and form an air column structure.

3. Inflation and sealing During the forming process, the production line injects air into the air column through the inflator, and then seals the air column through the sealing device to form a complete air column bag.

4. Cutting and output According to the set length, the production line cuts the air column bag and outputs the finished product to the collection device.

Application fields of air column bag making machine

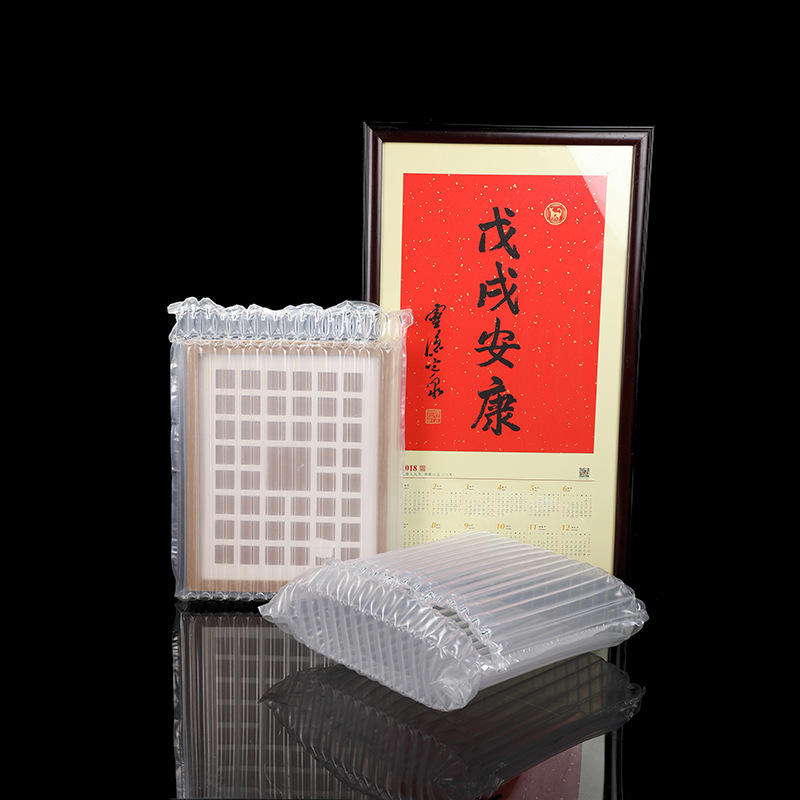

1. Electronic product packaging: air column bags are widely used in the packaging of electronic products such as mobile phones, computers, tablets, etc., providing excellent cushioning protection.

2. Glass products and fragile products packaging: The cushioning performance of air column bags makes them an ideal packaging material for fragile products such as glass products and ceramics.

3. Furniture and home appliance packaging: air column bags can be used for the packaging of large products such as furniture and home appliances, providing lightweight and high cushioning solutions.

4. Logistics and warehousing: In the logistics industry, air column bags are widely used for internal cushioning and external packaging of products to reduce the risk of damage during transportation.