Introduction

As e-commerce and global logistics continue to grow, the demand for reliable, lightweight, and cost-efficient protective packaging is increasing rapidly. Among all modern cushioning materials, air column bags have become one of the most popular choices for packaging fragile items such as electronics, cosmetics, wine bottles, small appliances, and more.

But how are these air column bags produced?

This is where the air column cushion bag making machine plays a crucial role. If you're new to this industry or planning to start a production line, this guide will help you understand everything from the basics to the manufacturing process, machine functions, advantages, and applications.

Why would a company choose to build its own air column cushion bag production line?

Many newcomers to air column packaging ask:

"Why should I buy a large air column bag making machine? Wouldn't it be easier to just buy finished products?"

If your business is small, outsourcing packaging is indeed more flexible; however, once production reaches a certain scale (e.g., hundreds of thousands to millions of air column bags per month), establishing your own production line offers significant advantages:

1. Reduced Unit Costs (More Prominent with Larger Scale)

Purchasing finished air column bags involves significant processing costs. With your own production line, costs mainly come from film materials, labor, electricity, and depreciation. Therefore, a 20-50% lower unit cost compared to outsourcing is common.

2. Enhanced Supply Chain Stability

During peak seasons or cross-border e-commerce promotional periods, external suppliers often experience supply shortages. With your own production line, most of the production capacity can be adjusted independently.

3. Customizable Specifications

You can flexibly produce:

*Air column bags with different numbers of columns

*Different lengths and widths

*Customized logos or custom colored film materials

*Packaging structures for special products (wine bottles, cans, monitors, etc.)

This is difficult to achieve with purchased finished products.

4. Easier Quality Control

Creating your own production line gives you direct control over important factors like sealing quality and airtightness. This is especially good for glass products, precision instruments, and high-end electronics.

What Is an Air Column Cushion Bag Making Machine?

If you're new to the protective packaging industry, you may have heard of the air column cushion bag making machine but still wonder what exactly it is and how it works. This machine is not a small tabletop model — it is a large-scale industrial air column bag production line designed for factories that need to manufacture air column rolls, Q-shaped bags, L-shaped bags, U-shaped bags, or fully customized inflatable packaging.

In simple words:

An air column cushion bag making machine is a high-efficiency production line that converts PE/PA co-extruded film into protective air column bags used for electronics, cosmetics, wine bottles, home appliances, online retail packaging, and other fragile goods.

What Materials Does It Use?

To produce strong, puncture-resistant air column bags, the machine uses:

✔ PE/PA (nylon) co-extruded film

*High barrier property

*Better sealing strength

*Excellent elasticity and pressure resistance

Common thickness options

*60 microns

*75 microns

*80 microns

*Custom film thickness

This material ensures each air column can maintain air pressure during long-distance transportation.

How Does an Air Column Cushion Bag Making Machine Work?

Here's what happens inside the machine during production:

Step 1. Film Unwinding

The machine begins by feeding pre-printed and pre-designed PE/PA film from large film rolls.

*Stable tension control

*High-speed film feeding

*Compatible with multiple film widths and thicknesses

This ensures smooth operation during long production cycles.

Step 2. Heating and Folding

Next, the film passes through a heating and folding system.

The machine precisely folds the film into the correct shape needed for creating columns, chambers, and sealing layers.

This stage determines the final durability of each column.

Step 3. High-Strength Heat Sealing

This is the most important part of the process.

Through multiple heat-sealing wheels, the machine:

*Forms each independent air column

*Creates airtight edges

*Ensures uniform sealing strength

*Guarantees protection performance after inflation

A good air column bag production line will have stable sealing temperature and consistent sealing pressure, so every bag has the same protection quality.

Step 4. Cutting & Bag Formation

The machine then cuts the material into:

*Roll-type air column film

*Pre-cut bag types

*Q/L/U-shaped bags

*Customized air column packaging

This depends on the customer’s requirements and mold settings.

Step 5. Finished Air Column Bag Output

The final products can be used directly on air column inflation machines or automated packaging lines.

This completes the full manufacturing cycle.

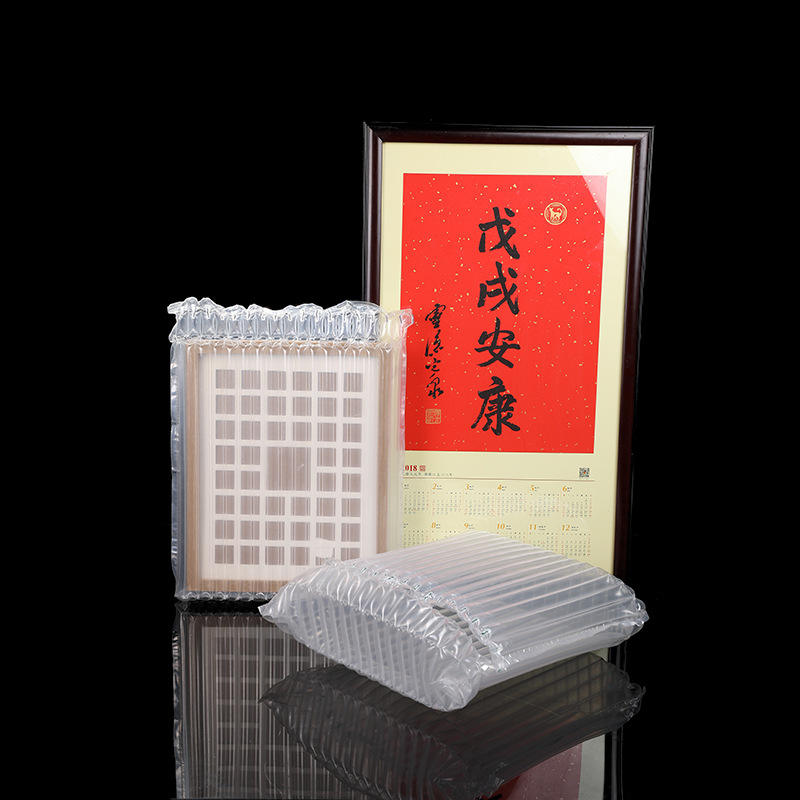

What Products Can This Machine Make?

The machine can produce a wide variety of protective packaging, including:

✔ Air Column Rolls

Used for universal protection and used on inflation machines.

✔ Q-type Bags

Commonly used for electronics and small appliances.

✔ L-type / U-type Bags

For wine, glass bottles, jars, and tall cylindrical products.

✔ Full Custom Packaging

Designed for product-specific shapes.

This versatility makes it ideal for packaging factories, e-commerce support suppliers, logistics companies, and manufacturing brands.

What Are the Advantages of Using an Air Column Cushion Bag Making Machine?

1. High Protection Performance

Each air column works independently — even if one column leaks, the others remain inflated.

2. Lightweight and Space-Saving

Air column bags are shipped flat → saving up to 95% warehouse space.

3. Lower Transportation Cost

Less weight means lower shipping fees for your customers.

4. Eco-Friendly & Clean

No debris, no chemical smells, and recyclable material.

5. High Production Efficiency

Suitable for medium to large factories requiring stable output.

6. Supports Diverse Packaging Needs

Q bag, L bag, U bag, roll film — all can be produced on one line.

Who Should Invest in This Machine?

You should consider investing in an air column bag production line if you are:

1. A packaging product manufacturer

2. An air cushion packaging supplier

3. A logistics/warehousing support company

4. An e-commerce packaging wholesaler

5. A protective packaging brand owner

6 . A factory that wants to replace foam or EPE packaging

The demand continues to grow globally, especially from Europe, North America, and Southeast Asia.

Conclusion

The air column cushion bag making machine is a crucial piece of equipment for any business looking to produce high-performance protective packaging. It offers high protection, lower shipping costs, flexible customization, and wide industry applications. Whether you're new to the industry or planning to expand your packaging product line, understanding how this machine works can help you make better decisions and enter the market with confidence.

Our services:

After a customer purchases a machine, if they encounter difficulties with installation, debugging, or other operations, we will dispatch engineers and project managers to the local area to install and debug the machine until it is in successful production.