Introduction

In today's fast-paced and competitive packaging industry, more and more manufacturers want to improve their core competitiveness and choose to invest in the production equipment of raw packaging materials, and the fully automatic honeycomb paper making machine is one of the options. Then, when investing in this large equipment, it is also important to ensure what after-sales support and maintenance your machine has. This guide will walk you through the basic steps and best practices for maintaining a honeycomb paper making machine after purchase.

Before we begin, let's first understand the definition of honeycomb paper making machine.

What Is The Honeycomb Paper Making Machine?

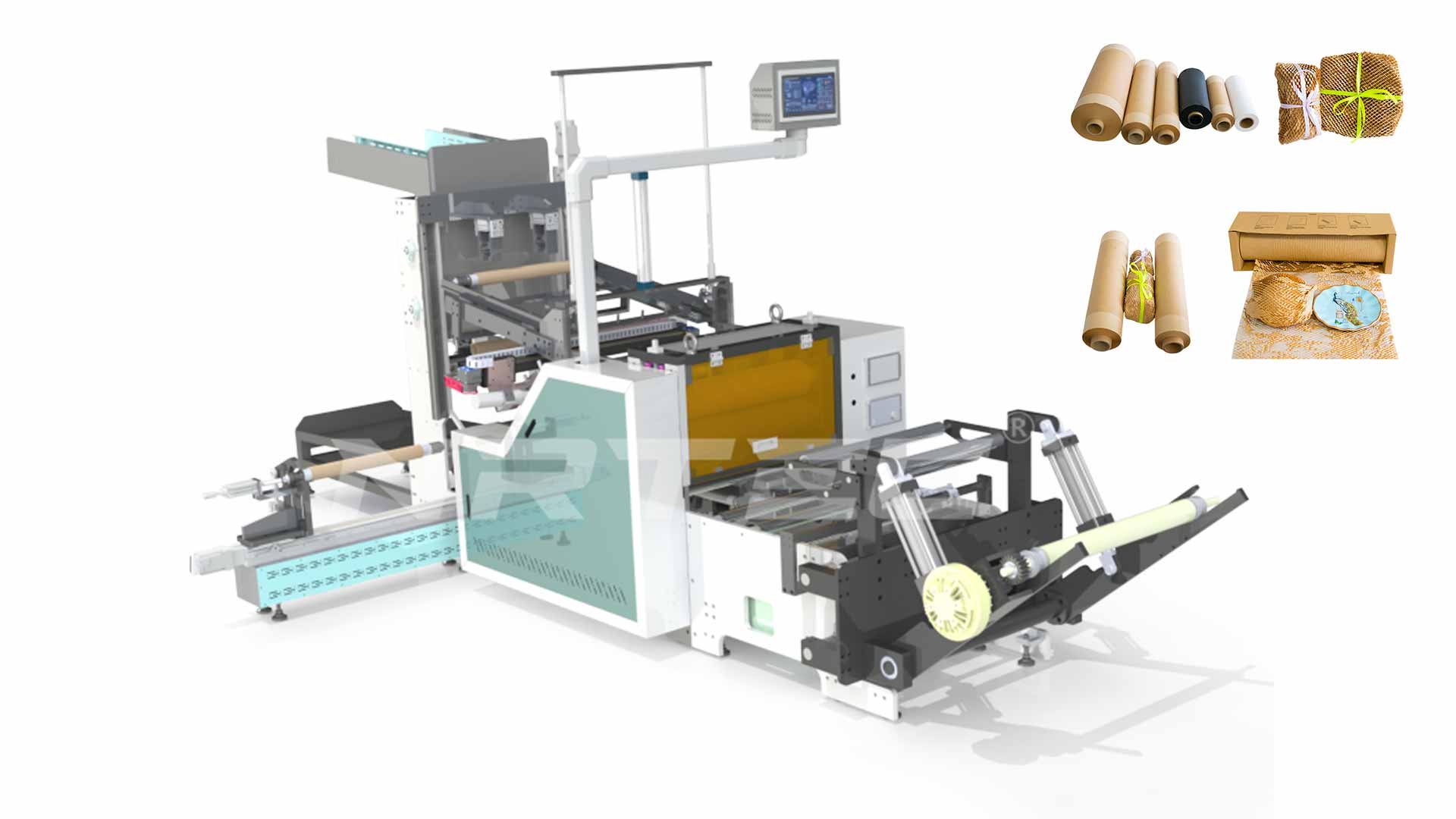

Honeycomb paper making machine, also called honeycomb paper cutting machine, is a machine that cuts kraft paper rolls into rolls of honeycomb packaging paper. The biggest feature of this machine is that the whole process is automatic, using hydraulic feeding method, and no human intervention is required.

The machine can automatically complete winding, rewinding and changing reels. The collection method is friction collection. There is a special paper roll storage area, which can hold up to 40-50 rolls of paper rolls. The die-cutting roller adopts modular design, which is easy to disassemble and convenient for later management.

Using special cold punching die steel, the cut honeycomb paper is a popular and widely used packaging material, and it is also a sustainable alternative to traditional plastic packaging. It has the characteristics of lightweight, durable and flexible, customizable and roadside recyclable products, and is an environmentally friendly packaging material used to protect fragile and sensitive items.

The Importance Of After-Sales Support

1. Improve efficiency and reduce machine downtime

Regular preventive maintenance of the machine can pre-empt potential and exposed problems of the machine to control and solve them in advance, avoiding failures during the production process that affect production progress.

2. Extend the service life of the machine

Regular maintenance can significantly extend the service life of the machine and reduce unnecessary expenses and manpower and time costs caused by frequent replacement of machine parts.

3. Optimize performance

Develop a standardized maintenance and overhaul plan that conforms to the industry and product use, so that the machine can run more efficiently and stably, thereby improving product quality and productivity.

Key Components Of After-sales Maintenance

1. Routine inspection: Set up regular maintenance record forms and record them. After use, check the use of the machine and the daily wear of the parts and keep records for reference data for the later maintenance of the machine.

2. Lubricant Use: Use appropriate lubricants on accessories that are often worn to reduce the possibility of premature damage and failure due to friction.

3. Calibration: Regularly calibrate important parts of the machine to ensure accurate and consistent cutting.

4. Filter Maintenance: Clean or replace filters as needed to maintain efficient air and material flow.

The Role Of After-Sales Support In Business Success

Professional and orderly after-sales support not only ensures that your honeycomb paper making machine can operate normally and efficiently, but also verifies the success of the project invested by the enterprise. By giving priority to and correctly performing product maintenance on the honeycomb paper making machine, you can ensure that you get:

*Efficient production: able to meet the production needs of large quantities of honeycomb paper

*Customizability: honeycomb paper roll width or machine logo, color, etc. can be customized according to needs

*Brand impression: maintain a reputation for reliability and quality

Best Practices For After-sales Maintenance

*Basic training of employees: Ensure that operators can receive basic product use training to ensure that they can perform routine inspections and maintenance on the product after use.

*Keep regular maintenance records: Record the use of each accessory and product in detail, so as to track the data of subsequent product updates and parts replacements, and ensure the normal use of the product.

*Find regular manufacturers to purchase parts: When replacing parts, you can refer to the applicable voltage, power, etc. of the relevant products before making a selection. When appropriate, you can purchase directly from the original manufacturer to ensure product compatibility and performance.

*Follow the manufacturer's guidelines: Follow the manufacturer's recommended maintenance plan and procedures.

*Emergency support: Develop an emergency maintenance plan, including a list of trusted service providers and contact information.

Conclusion

Honeycomb paper making machine is one of the important and effective investments in the current packaging industry. It is crucial to pay attention to and correctly grasp after-sales support and maintenance, which can maximize the value of your investment, and also ensure that the machine runs at optimal performance, reduce downtime, and improve return on investment.