Honeycomb Paper Roll Making Machine Working Principle

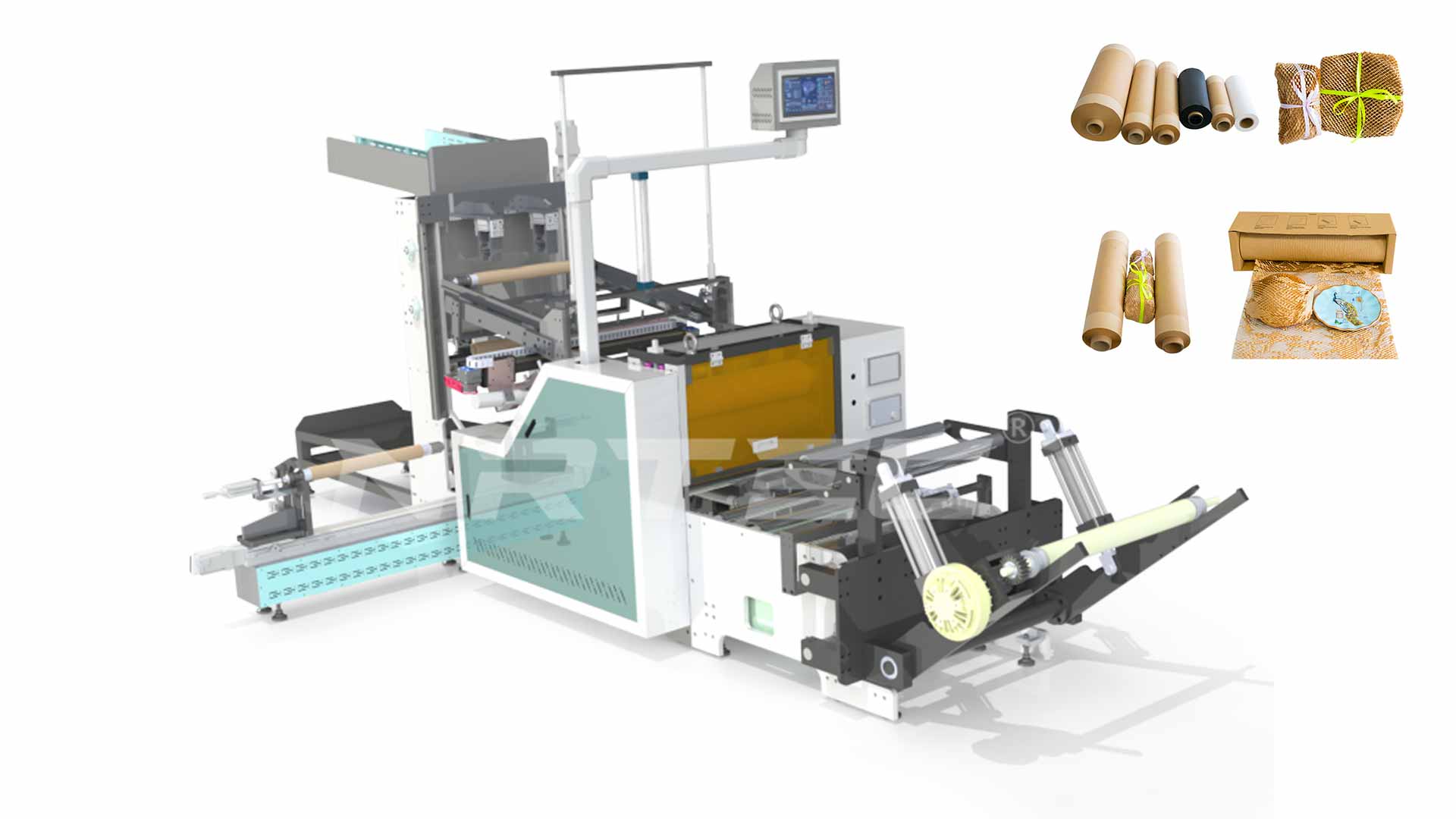

The overall structure of the honeycomb paper roll making machine is simple, intelligent and flexible. It mainly consists of paper feeding system, pressing system, drying forming and cutting system, conveyor belt mechanism system, touch screen control system and other parts. It mainly cuts kraft paper rolls into honeycomb paper rolls of different widths for packaging items, transportation filling protection, etc.

Honeycomb paper roll making machine produces honeycomb paper. Due to its wide use in the packaging industry, the popularity of honeycomb paper is also obvious from the perspective of cost and use.

The softness and elasticity of honeycomb paper can effectively protect the items transported in the box, and its light weight can save transportation costs.

What Is The Honeycomb Paper Roll Making Machine?

Honeycomb paper roll making machine is a precision equipment specially used for mass production of honeycomb paper rolls. Honeycomb paper is made of kraft paper through special processing technology. After the steps of pressing, drying, cutting and forming by the honeycomb paper making machine, it finally forms honeycomb packaging paper.

Honeycomb paper is a sustainable alternative to traditional plastic and foam packaging. It is lightweight, durable, elastic and has high-quality cushioning performance. Its appearance presents a hexagonal polygonal product structure, which can effectively wrap the transported items and can be stretched at a ratio of 1:1.7. It can wrap items of various shapes. It is also because of this feature that it is favored by various packaging industries.

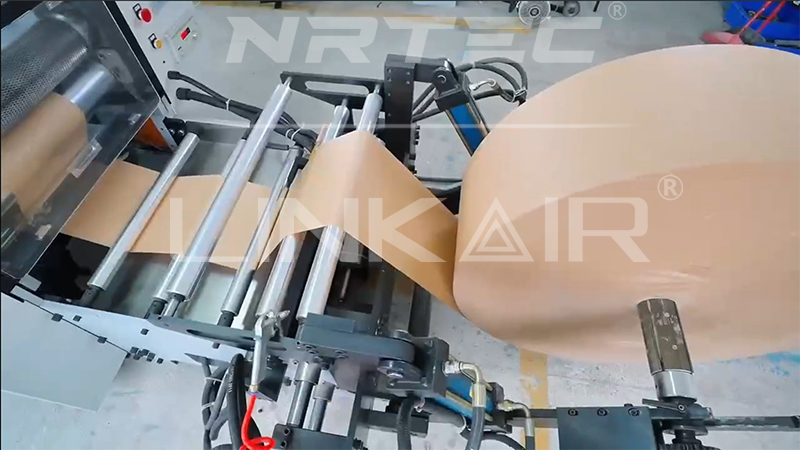

In addition, the honeycomb paper making machine can automatically complete the entire production work and reduce the error of manual intervention. It can automatically expand the die-cut kraft paper into a 3D honeycomb structure. It has an automatic feeding system and automatic paper tube loading, automatic air shaft loading, automatic air extraction and placement of air shafts. The process is all automatic. In addition, it is equipped with an automatic deviation correction system, which can accurately cut the honeycomb packaging paper without deviation, reducing the possibility of manual intervention.

Its 280m/min running speed has high throughput and high stretch ratio, which can increase production and packaging speed. It is often used in industries such as retailers, e-commerce and logistics warehouses.

Honeycomb Paper Making Machine Components

*The engine is the main core power

*The control screen with touch adjustment settings

*The upper air shaft and exhaust system

*The transmission helps to transmit power from the engine to the wheels

*The braking system allows the machine to stop in an emergency

*The transmission system allows the honeycomb paper to be transmitted and collected

Honeycomb Paper Roll Making Machine How It Works?

The honeycomb paper making machine is a machine that can fully automatically and composite large rolls of kraft paper rolls into single rolls of honeycomb paper rolls. The honeycomb paper can be 50cm/38cm/30cm in different widths. By cutting the surface of the kraft paper into a specific shape, it will present a honeycomb shape after unfolding, so as to enter the next stage for rolling, cutting the required size of the honeycomb paper, and transmitting it to the collection belt through the transmission system for collection.

And the honeycomb paper has a certain softness and can be widely used to package various fragile valuables, ceramics, cosmetics and automotive products, gift decorations, etc.

Honeycomb Paper Roll Making Machine Advantages

From the above content, it can be seen that the honeycomb paper making machine is a professional equipment for producing single rolls of honeycomb paper. It can be fully automatically and efficiently mass-produced. Its significant advantages also benefit various industries and e-commerce industries.

1. Save procurement costs

With this machine, you can mass-produce honeycomb paper rolls yourself, and in the process reduce procurement costs and many cumbersome procurement processes.

2. Expand the business chain

Help manufacturers expand the original business chain structure, and provide the produced honeycomb paper to local logistics warehouses, retailers and other e-commerce industries.

3. 100% recyclable packaging material

The honeycomb paper is made of natural kraft paper, which is fully recyclable and biodegradable. It is strong and durable, and can be used to package various items and provide buffer protection.

4. Improve efficiency

The machine runs efficiently at a speed of 280 meters/minute. According to the working hours of 8 hours a day, it can produce 150/160 rolls a day, thus saving production costs.

Summary

Investing in a fully automatic honeycomb paper making machine is an investment plan with more advantages than disadvantages. After understanding its relevant working principles and functions, you can better understand and use the machine correctly. If you want to know more, you can contact our professional team at any time. We will provide professional advice and send you product-related operation videos and maintenance precautions.