Honeycomb Paper Making Machine:How It Works

Understanding and knowing the correct use of the honeycomb paper roll making machine production line plays an important role in improving production efficiency and product quality. The following are some key steps and tips to ensure that you can use the honeycomb paper production line efficiently and correctly.

1. Understand the working principle of the equipment

The honeycomb paper cutting machine production line consists of multiple parts, including paper preparation system, cutting and forming system, honeycomb paper roll conveyor, drying and pressing system and whole machine control system. Understanding the function and working principle of each part is the basis of operation.

2. Choose the right raw materials

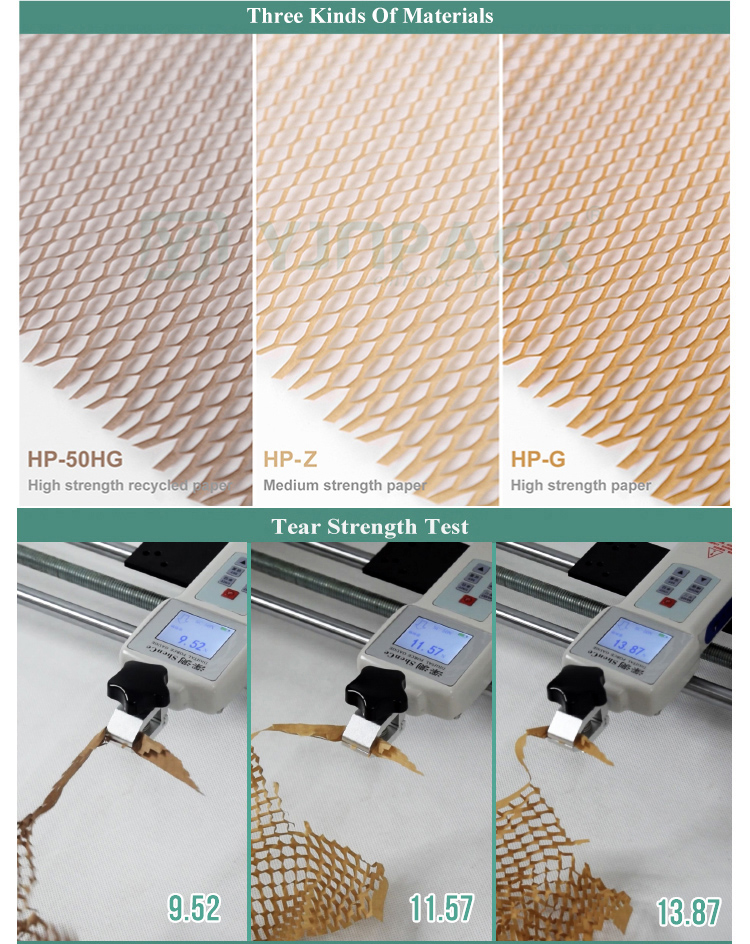

High-quality raw materials are the prerequisite for ensuring the quality of honeycomb paper. Using 80gsm high-strength kraft paper as raw material, this paper has a good stretch ratio (1:1.7), which can produce higher quality honeycomb paper rolls to provide better product protection.

3. Ensure that the equipment is properly installed and debugged

Before starting production, make sure that all equipment has been properly installed and properly debugged. This includes checking the lubrication of the bearings and the settings of the system, the settings of the automatic tube loading device and the tightening of the mechanical components, ensuring that the electrical system is working properly, and calibrating the control system.

4. Preparation before operation

Before starting production, the production line needs to be preheated to ensure that the paper can be cut evenly when passing through the cutting roller. In addition, the spacing of the cutting rollers needs to be adjusted to meet the production needs of honeycomb paper of different thicknesses.

5. Monitoring the production process

The honeycomb paper cutting machine is fully automatic in production and automatic cutting and winding, but during this production process, technicians still need to continuously monitor the operating status of the production line, including parameters such as speed, temperature and pressure. This helps to promptly discover and solve problems that may arise in the production process.

6. Maintenance and cleaning

Maintain and clean the production line regularly to keep it in good operating condition and extend its service life. This includes cleaning the cutting rollers, replacing worn blades, and lubricating mechanical parts.

7. Safe operation

When operating the honeycomb paper roll making machine, safe operating procedures must be followed, including wearing appropriate protective equipment, using safety tools, and conducting safety checks before and after operation.

8. Quality control

During the production process, samples are regularly taken to check the quality of the honeycomb paper, including its thickness, strength and appearance. Linkair's honeycomb packing paper will be labeled in the honeycomb paper roll tube core in accordance with regulations so that subsequent products can trace the production source, and this also helps to ensure that the product meets quality standards and adjust the production process in time to improve product quality.

By following the steps and tips above, you can ensure the effective operation of your honeycomb paper production line, thereby improving production efficiency and product quality. Remember, continuous learning and improvement are the key to keeping your production line running efficiently.

What are the common faults of honeycomb paper making machine?

1. Uneven glue coating: Improper quality of glue coating roller and improper setting of glue coating process parameters may lead to uneven glue coating and affect the quality of honeycomb paper. The glue coating roller needs to be checked and maintained regularly to ensure its cleanliness and good operation.

2.Cutting problem: If the cutting mechanism is improperly adjusted or worn, it may cause uneven cutting or excessive paper scraps. Regularly maintain and calibrate the cutting mechanism to ensure cutting accuracy.

3.Uneven honeycomb forming: If the honeycomb forming mechanism is offset or damaged, it will cause uneven honeycomb forming. It is necessary to check whether the honeycomb forming mechanism is aligned and ensure that all parts are working properly.

4.Electrical system problems: Electrical system failure may cause the production line to stop working. It is necessary to check the electrical connection and control system regularly to ensure its stable operation.

5.Equipment jam: If there are impurities or improper installation of paper rolls during the kraft paper conveying process, it may cause equipment jams. It is necessary to ensure the quality of raw materials and check the installation of paper rolls regularly.

6.Mechanical failure: Wear or damage of mechanical parts without regular maintenance may also cause unstable operation of the production line. Mechanical parts need to be maintained and replaced regularly.

7.Improper operation: If the operator does not follow the operating procedures, it may cause equipment failure or product quality problems. Operators need to be trained regularly to ensure that they understand the operating procedures and safety regulations.

8.Improper temperature and humidity control: The temperature and humidity of the production environment have a significant impact on the quality of honeycomb paper. The temperature and humidity of the production environment need to be strictly controlled to ensure product quality.

Conclusion

When you choose to invest in a new product, you need to have a deep understanding of its correct use and some common faults and be able to take appropriate preventive and maintenance measures in time, which can ensure the stable operation and product quality of the honeycomb paper roll making machine production line, and also allow production to proceed smoothly.