Why choose our air column bag making machine production line?

1. Reduce costs and increase efficiency

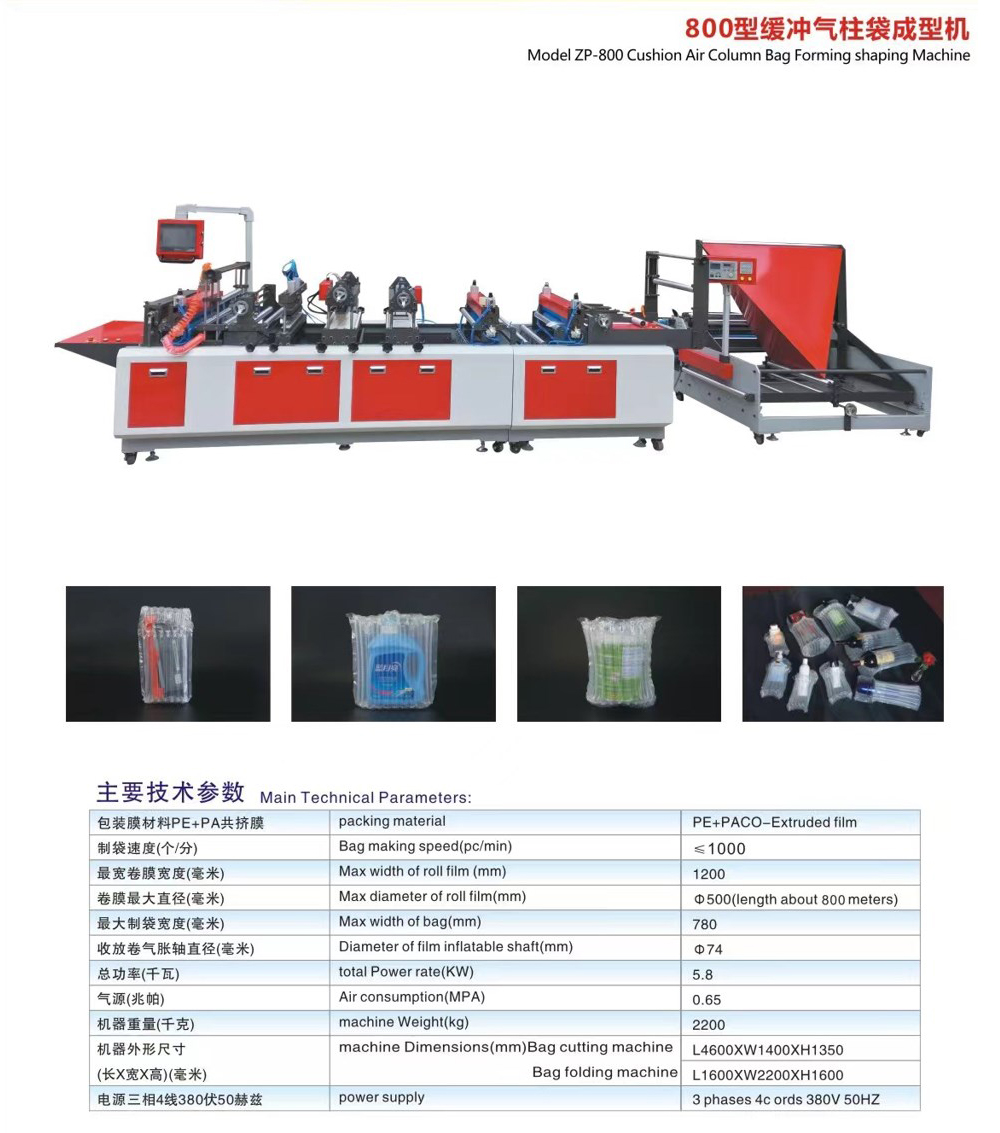

*The automated air column bag making machine production line integrates roll film forming, inflation, sealing, and slitting functions. The daily output of a single machine can reach more than 100,000 pieces, reducing manual dependence by 30%-50%.

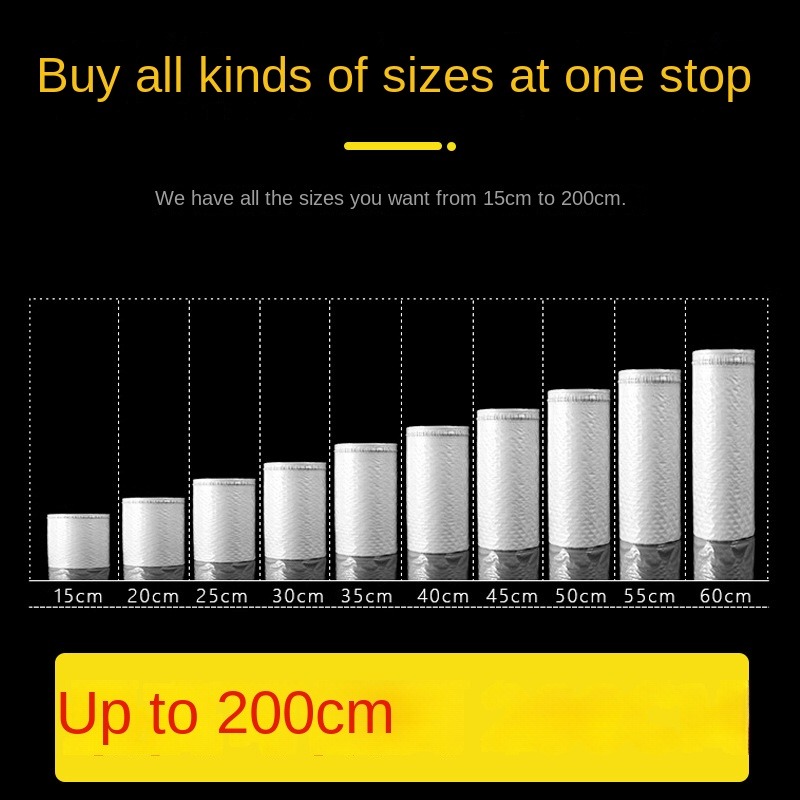

*Supports customized air column size (10cm to 1.5m), adapting to the packaging needs of multiple industries such as electronic products, furniture, and medical devices.

2. Energy saving and environmental protection

*Adopting servo motor drive, the energy consumption is reduced by 25% compared with traditional models, in line with the EU CE energy efficiency standards.

*Compatible with degradable PE/PA co-extruded film materials, helping customers meet the requirements of European EPR environmental regulations.

3. Intelligent and stable operation

The PLC intelligent control system is equipped with a multi-language interface (English/Turkish/Vietnamese, etc.), real-time monitoring of parameters such as air pressure (0.3-0.6MPa) and temperature (160-200℃) to ensure a yield rate of ≥98%.

How to use the automatic air column bag making machine?

Step 1: Installation and debugging

*Site requirements: flat hardened ground, power supply 380V/50Hz (European version can adapt to 220V), and reserve 1.5 meters of maintenance space around the equipment.

*Pre-start inspection: confirm the oil level of the air pump, the cleanliness of the heating plate, and the tightness of the transmission chain (recommended tension value 5-8kg).

Step 2: Daily production process

Loading → 2. Set parameters (film roll tension/sealing temperature/slitting length) → 3. Start automatic inflation detection → 4. Finished product stacking and packaging

Key tips: The first piece needs to be manually sampled for air tightness testing (immersion method or pressure maintenance for 24 hours observation).

Step 3: Changeover adjustment

After replacing the mold and roll film, the infrared alignment sensor needs to be recalibrated to avoid slitting offset.

Air column bag making machine:Safe operation and precautions

⚠️ High-risk link warning

*High temperature area: The sealing module is prohibited from being touched with bare hands during operation, and it needs to be cooled to below 60°C before cleaning after shutdown.

*Air pressure safety: Check the gas tank safety valve regularly (once a month), and the pressure is strictly prohibited from exceeding the 0.8MPa red line.

✅ 3 key points to extend the life of the equipment

*Environmental management: The workshop humidity must be maintained at <70%, and the dust particle filtration level is ISO 15.

*Consumables specification: Only use special film rolls with a thickness of ≤0.08mm and a friction coefficient of <0.3. Poor quality raw materials are prone to blockage.

*Anti-static measures: The grounding resistance of the equipment is ≤4Ω. It is recommended to install an ion fan to eliminate the static electricity of the film material.

Air column bag making machine:Regular maintenance schedule

| Maintenance cycle | Operation content | Required tools |

| Daily | Clean up cutter debris and add guide rail lubricant | Vacuum cleaner/lithium grease |

| Monthly | Detect the resistance value of the heating plate and replace the air pump filter | Multimeter/HEPA filter |

| Every six months | Calibrate the pressure sensor and fully tighten the circuit connector | Calibrator/anti-static gloves |

Troubleshooting Quick Reference Guide

Problem 1: The seal is not firm

Reason: Insufficient temperature/Poor temperature resistance of membrane material → Solution: Increase the temperature by 10°C or replace the membrane material with a high melting point

Problem 2: Uneven inflation

Reason: Nozzle blockage/Unstable air pressure → Solution: Clean the nozzle with a 0.5mm needle and check the air storage capacity of the air compressor