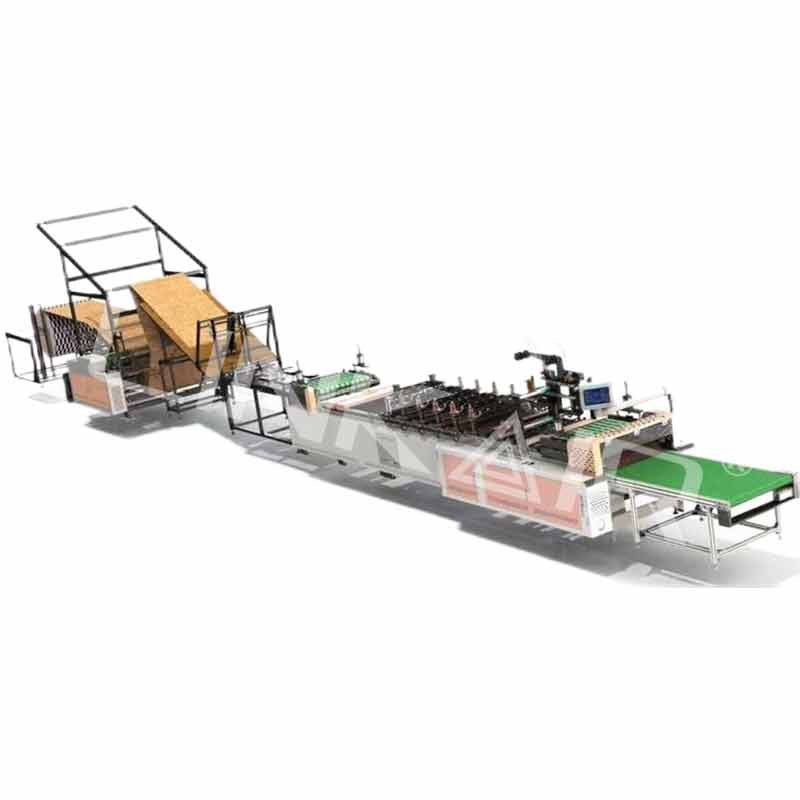

Full Automatic Honeycomb Paper Making Machine

The fully automatic honeycomb paper making machine can automatically produce honeycomb paper rolls on demand and intelligently, reducing manual intervention and improving production efficiency by at least 20%. For the packaging industry, honeycomb paper is a lightweight and durable cushioning and protective packaging material, and 100% recyclable.