Introduction

Driven by the dual waves of e-commerce logistics and green economy, the packaging industry is facing an urgent need for efficiency upgrades and sustainable transformation. Amazon Paper Padded Mailer Bag Making Machine, with its unique material adaptability and automated production capabilities, is becoming a core tool for the manufacturing industry to break through cost bottlenecks and respond to policy supervision.

This article will analyze how this equipment reshapes the logic of packaging manufacturing from three dimensions: technical characteristics, production efficiency, and industrial impact, and provide a transformation handle for the manufacturing industry.

Amazon Paper Padded Mailer Bag Making Machine Advantages

1. Material innovation: a double breakthrough in lightweight and high strength

The core of honeycomb paper mailer envelope bags lies in their bionic structure - the hexagonal honeycomb core layer is compounded with the face paper to form a honeycomb-like mechanical support system. This structure is achieved through the high-precision molding process of the manufacturing machine, bringing the following performance advantages:

*50% increase in compressive strength: At the same thickness, the compressive strength of honeycomb paper far exceeds that of corrugated paper, and can withstand a pressure of 15kg/cm² (data source: ISTA transportation test standards), which is suitable for packaging of fragile items such as electronic products and precision instruments.

*30% weight reduction: Taking A4 size envelope bags as an example, traditional corrugated paper bags weigh about 80g, while honeycomb paper bags only weigh 56g, significantly reducing logistics costs (international express delivery saves an average of US$0.8 per kilogram in freight).

2. Production efficiency: full process automation and flexible production

The core value of the amazon paper padded mailer bag making machine lies in "integrated output from raw materials to finished products":

*High-speed continuous production: using kraft paper roll feeding system, combined with hot melt adhesive instant bonding technology, the single machine production capacity can reach 2000-3000 pieces/hour, and the efficiency is 3 times higher than that of traditional semi-automatic equipment.

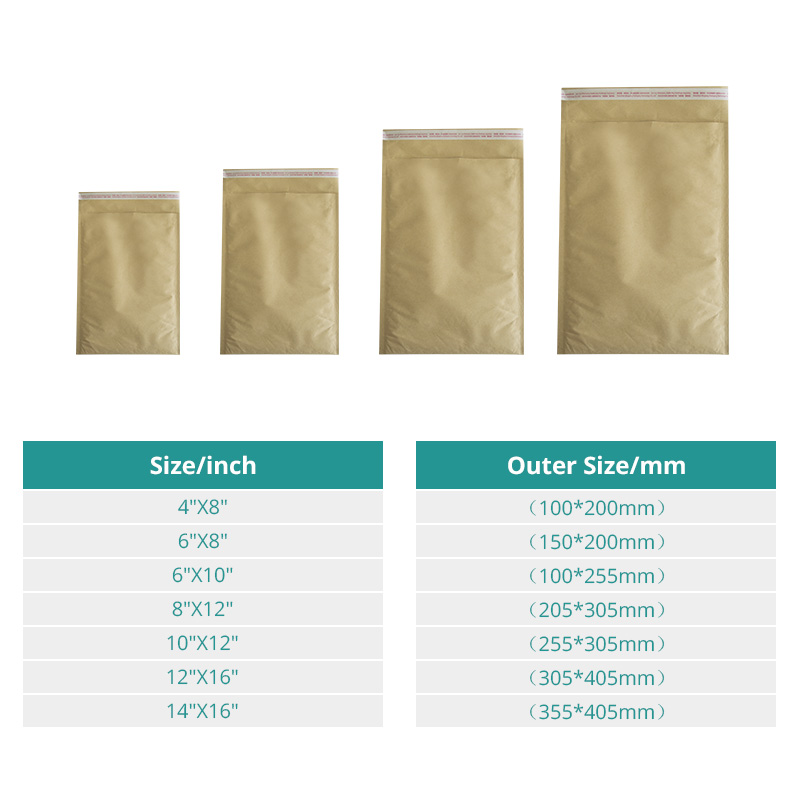

*Quick switching of multiple specifications: the envelope size (such as A2 to A6) and thickness (3mm-15mm) are preset through the CNC system, and the switching time is less than 5 minutes, which can meet the needs of small batch customized orders (for example: limited edition packaging during the cross-border e-commerce promotion season).

*The waste rate is less than 2%: the precise die-cutting and residual material recycling system can crush the scraps and re-press them into filling materials, achieving almost zero waste.

Case: After a German automotive parts supplier introduced the honeycomb paper mailer bag making machine, the manpower of the packaging line was reduced by 60%, and the delivery cycle was shortened from 7 days to 48 hours.

Disruptive impact on manufacturing

1. Cost structure optimization: from "scale dependence" to "precise cost reduction"

* Raw material cost savings: The honeycomb paper core layer can be mixed with recycled pulp (accounting for up to 70%), and the raw material cost is 25%-40% lower than that of pure wood pulp corrugated paper.

* Energy consumption and carbon emissions are reduced:

The production process does not require high-temperature plasticization (traditional plastic packaging requires processing at more than 200°C), and energy consumption is reduced by 60% (data source: Carbon Trust).

The equipment is equipped with a photovoltaic power interface, which meets the EU's "Carbon Border Adjustment Mechanism" (CBAM) tracking requirements for carbon emissions of imported products.

* Inventory pressure relief: The on-demand production model reduces the accumulation of semi-finished products and reduces storage space occupancy by 35%.

2.Policy compliance and market access

*Break through environmental trade barriers:

Honeycomb paper mailer envelope bags are 100% recyclable and degradable, complying with the EU's "Packaging and Packaging Waste Regulation" (PPWR) requirements for plastic packaging alternatives, avoiding the imposition of a plastic tax of up to 900 euros per ton.

Paper sources certified by the FSC (Forest Stewardship Council) can meet the sustainable procurement standards of companies such as Walmart and IKEA.

*Seize the mindset of green consumption:

62% of consumers worldwide are willing to pay a premium for environmentally friendly packaging (McKinsey 2023 survey), and brands using honeycomb paper bags have an average 18% increase in conversion rates on e-commerce platforms.

3. Collaborative upgrading of the industrial chain

* Upstream integration: Pulp suppliers need to develop special honeycomb paper with high bulk and low grammage to promote the iteration of papermaking technology.

* Downstream application expansion:

Cold chain logistics: Honeycomb paper bags coated with hydrophobic coating can withstand low temperatures of -20°C and replace expanded polystyrene (EPS) for fresh food transportation.

Industrial heavy packaging: By increasing the density of the core layer, industrial honeycomb paper mailer envelope bags with a load-bearing capacity of 50kg can be produced to enter the automotive parts and mechanical parts market.

* Equipment service transformation: Manufacturers can provide a one-stop service of "equipment + consumables + certification", shifting the profit model from hardware sales to long-term service subscription.

Future trends: Reconstruction of competitiveness from equipment to ecology

1. Technology integration: intelligence and IoT empowerment

* Real-time quality monitoring: Built-in sensors can detect parameters such as cardboard moisture content and glue viscosity, automatically adjust production parameters, and increase the yield rate to 99.5%.

* Remote operation and maintenance: Predict equipment failures (such as die wear warning) through the IoT platform, reduce downtime losses, and reduce customers' comprehensive operation and maintenance costs by 30%.

2. Construction of a closed loop of circular economy

* Recycling network co-construction: Equipment manufacturers and logistics companies establish honeycomb paper bag recycling points, which are directly returned to the production line after crushing, realizing the "user-manufacturing-regeneration" closed loop.

* Carbon asset realization: Every ton of honeycomb paper mailer bags produced can reduce 1.2 tons of CO₂ equivalent emissions, and carbon credits can be traded in the EU carbon market to create additional income.

Conclusion

The honeycomb paper mailer envelope bag making machine is not only an upgrade of a single device, but also a fulcrum of the trinity of "material innovation + intelligent production + circular ecology" industrial transformation. For the manufacturing industry, its value has gone beyond cost savings and has become a strategic tool for coping with policy supervision, differentiated competition, and improving customer stickiness.