What is an automatic kraft paper mailer envelope bag making machine production line?

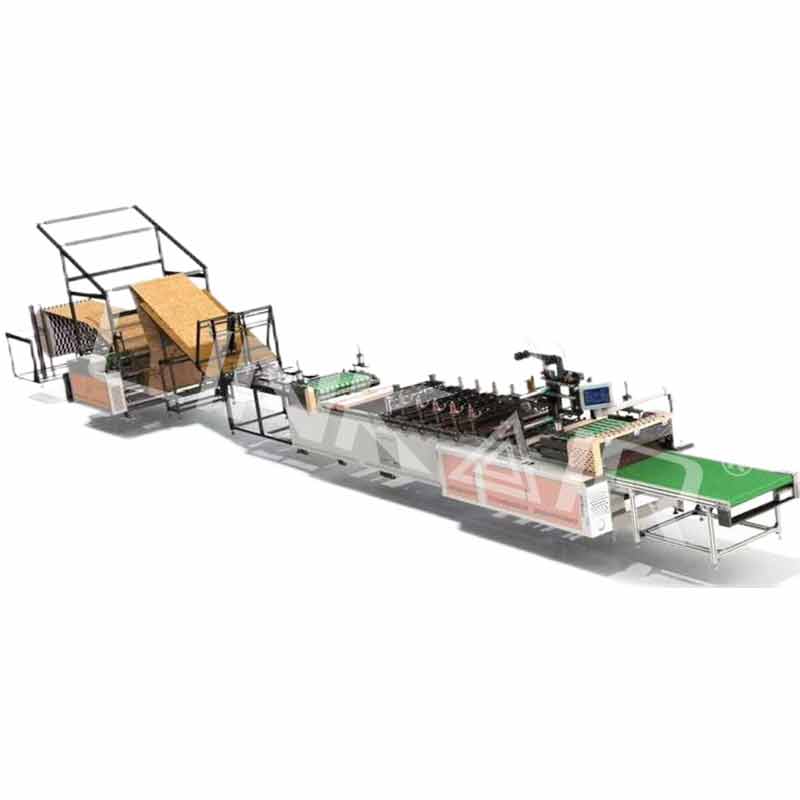

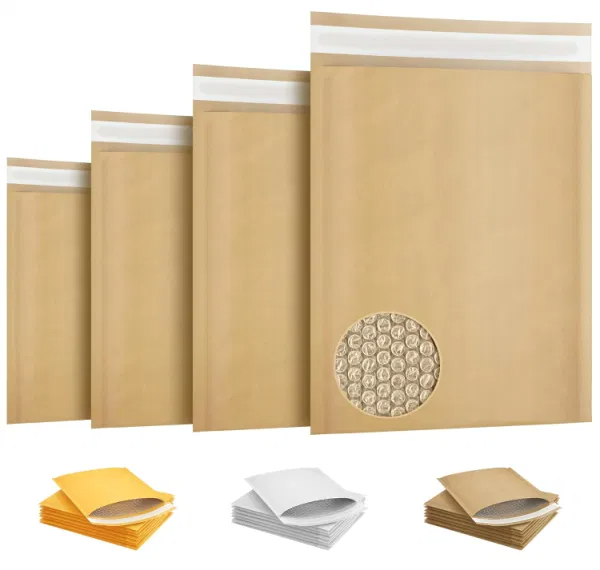

The automatic kraft paper bubble mailer envelope bag making machine production line is an efficient production equipment integrating compounding, sealing, folding and cutting. It is specially designed for manufacturing environmentally friendly packaging bags made of laminated kraft paper and polyethylene (PE) bubble film.

Its core functions include:

1. Full process automation: From material unwinding, hot roller bonding, folding and forming to hot pressing and sealing, precise cutting, the whole process is driven by the servo system and PLC programmable controller to achieve an efficient output of 260 pieces per minute.

2. Diversified applicability: It supports the compounding of various substrates such as kraft paper, aluminized film, and pearl cotton, and can produce fully compound two-side sealed and three-side sealed bags to meet the express packaging needs of lightweight goods such as books, crafts, and electronic components.

3. Environmental protection and durability: It uses degradable kraft paper and recyclable PE bubble film, taking into account both buffer protection performance and environmental compliance, which is in line with the green packaging trend of the global e-commerce and logistics industry.

Why choose the kraft paper bubble mailer envelope bag making machine production line?

1.Market demand driven: With the explosive growth of e-commerce logistics, the annual demand for lightweight and durable bubble envelope bags has increased by more than 20%. The production line can quickly respond to customized orders and adapt to the needs of multi-specifications and small batch production.

2. High efficiency and production capacity advantage: The production speed of 260 pieces/minute far exceeds that of traditional equipment (ordinary models are 20-80 pieces/minute), and with the automatic deviation correction and color mark tracking system, the yield rate is as high as 98%.

3. Significant cost-effectiveness: Adopting a direct sales model (such as Xinlibang Machinery), eliminating the agent's price increase link, the equipment investment return cycle is shortened by 30%.

4. Technological leadership: Equipped with Taiwan servo system, touch screen human-machine interface and intelligent lubrication system, it reduces the difficulty of operation and maintenance costs, suitable for large factories and small and medium-sized manufacturers.

How to use the kraft paper bubble mailer bag making machine production line correctly?

1. Material preparation: Ensure that the kraft paper weight is ≥90g, the bubble film thickness is 2-3mm, and the adhesive strip or hot melt adhesive meets the bonding strength requirements.

2. Parameter setting:

* Adjust the unwinding tension according to the bag type (bubble film ≤1200mm diameter, kraft paper ≤600mm).

* Set the bag making length (≤740mm) and width (≤500mm) through the touch screen, and enable the color mark tracking function to ensure cutting accuracy.

3. Production monitoring: Real-time observation of the heat sealing temperature (recommended 120-150℃) and pressure to avoid bubble film damage or weak bonding.

4. Maintenance points:

* Clean the residual glue stains on the hot roller daily and check the lubrication of the transmission chain.

* Calibrate the positioning accuracy of the servo motor and replace the gearbox lubricating oil every month.

* Annually overhaul the electrical system and upgrade the PLC control program to be compatible with new bag types.

Precautions for purchase and maintenance for beginners

1.Purchase suggestions:

*Matching requirements: Select the model according to the target bag type and bag type (such as three-side seal/two-side seal, or envelope bag with bubble bag or honeycomb paper lining) (select according to the required bag type).

*Verification parameters: Focus on checking the maximum unwinding width (≥1400mm), bag making speed (≥120 pieces/minute) and machine power (above 20KW).

*After-sales service: Give priority to suppliers who can provide door-to-door maintenance guidance (such as Linkair) if they encounter difficulties and cannot be repaired during the warranty period, and support remote online fault diagnosis and provide installation and operation videos.

2. Pit avoidance guide:

*Avoid "false power labeling" of low-priced models, and actually measure the full-load operation stability.

*Confirm that the equipment is compatible with the local voltage (three-phase 380V 50Hz) to prevent shutdown caused by power mismatch.

Conclusion

The kraft bubble mailer bag making machine production line has become the core equipment for the upgrading of the packaging industry due to its high production capacity, environmental protection properties and intelligent operation. Whether it is a large manufacturer or a start-up, choosing equipment with mature technology and perfect after-sales service will significantly enhance market competitiveness.

Through scientific use and regular maintenance, the life cycle value of the equipment can be maximized to meet the diversified needs of the global green packaging wave.