Why insist on using semi-automatic equipment and spend $12,000 per year?

Many factories using semi-automatic air column bagging machines face hidden losses:

*Labor cost loophole: 3 operators are required for film loading/sealing/packaging, while the fully automatic system only needs 1 operator.

*Material waste: Due to manual feeding, the film misalignment error is as high as 8-12% (while the automatic correction is only 0.5%).

*Overtime risk: Without 24/7 shifts, it is impossible to handle 10,000 emergency orders.

Three strategic upgrade paths for existing plants

1. Modular transformation: 60% cheaper than full replacement

*Target: Basic semi-automatic machine with mechanical stability

*Key upgrades:

-Add automatic film feeding module ($8,500) → Reduce 2 workers

-Install intelligent module detection system ($6,200) → Reduce 50% of quality inspection personnel

-Return on investment: 8-14 months

2. Mixed production mode: balance flexibility and efficiency

*Smart solution: retain 1 semi-automatic line for small batch customized orders + 1 fully automatic line for batch standard packaging bags

*Cost advantage: 35% lower initial investment compared to full automation

3. Energy recovery system: turn waste into treasure

*Heat recovery: reuse 70% of sealing heat energy (saving $180 per month in electricity bills)

*Side material reuse: integrated crusher converts waste film into recycled particles

ROI Breakdown: How Automation Cuts Costs in 18 Months

| Cost Factor | Semi-Auto | Full-Auto | Savings |

| Labor (3 shifts) | $64,200 | $21,400 | $42,800 |

| Material Waste | $18,000 | $1,500 | $16,500 |

| Energy Consumption | $9,600 | $6,200 | $3,400 |

| Total Annual Savings | $62,700 | ||

Case Study: Turkish Manufacturer’s 9-month Upgrade Journey

Challenges:

*Two old semi-automatic production lines struggling with 85% capacity utilization

*Frequent overtime during peak season

Solution:

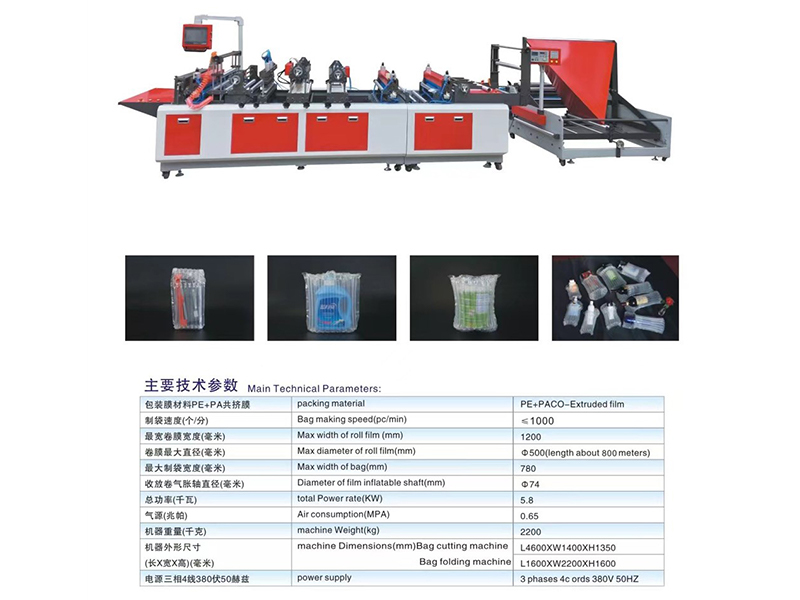

*Phase 1: Upgraded the automatic air column bag making machine production line system ($11,000) → increased production by 22%

Phase 2: Added smart data monitoring system ($7,500) → reduced downtime by 40%

Results:

*Full ROI within 13 months

*Won two new FMCG contracts with 48-hour delivery SLA

Next: Get your customized upgrade roadmap

☑️ Which modules can bring the fastest return on investment for your factory

☑️ Learn about the product features and functions of the fully automatic air column bag making machine system and get the video

☑️ Get your exclusive packaging solution